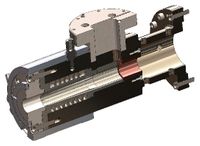

Plasticising Units

ETA Plasticising Units are the consistent outcome of the ETA barrier screw technology. Screw, feeding section, barrel and heating/cooling devices form a well optimised complete system.

ETA Plasticising Units are suitable for both new high performance extruders and for retrofitting to existing machinery. By incorporating an ETA Plasticising Unit an existing extruder can be converted into a modern machine with the performance characteristics of latest technology.

ETA Plasticising Units can be delivered in combination with motors and gear boxes as complete and efficient extruders. Due to their favourable torque behaviour and their excellent control of melt temperature even at higher screw speeds, ETA Barrier Mixing Screws are the appropriate solution for directly coupled motors without gear boxes. ETA Plasticising Units have been equipped with direct drives since 1998.

Characteristics of ETA Plasticising Units

- Complete system is tailor-made to the specific application

- High throughput and broad processing range

- Smooth bore or grooved barrel design

- Barrels for vented extruders with smooth or grooved feed section

- Grooved feed sections are preferably electrically heated and cooled with air (conventional water cooled systems are available)

- Efficient and robust heater/cooler units with ribbed ceramic blocks

|